We have recently spoken about boot polishinh. Today we explain the steps in how to polish your coastal rowing boats. Polishing a rowing boat involves several steps to ensure that the process is effective and that the boat is well-maintained. Make sure you are aware of the materials needed and the time for the polishing process. It is not a 5 minute job. Here’s a general guide on how to polish your coastal boat:

Materials You’ll Need:

- Boat polish or wax suitable for your boat’s material (fiberglass, carbon, etc.)

- Soft microfiber or cotton cloths

- professional Yacht or Boat cleaner (if the boat needs cleaning before polishing)

- Applicator pad or sponge

- Bucket of water

- Hose or water source

- Mild soap (if cleaning is necessary)

- Soft-bristle brush (for cleaning, if needed)

- Rubbing compound (for removing oxidation, if needed)

- Protective gloves

Before you start

If you’ve never polished before, try it by hand and practice. First take a soft cloth. Cut an old towel into 30 x 30 cm pieces. Floor wipes/pickups from the supermarket are also practical. After use, the cloths are put in the washing machine and used more often work with disposable gloves.

The chemicals are harmful to the skin and you keep the special smell on your fingers for hours. Working unprotected with polishing paste will leave you with dull skin on your fingertips for about a week. Rub various surfaces with and without abrasive paste. Compare the results. For the sake of the substance, if in doubt, leave out the paste containing abrasive

Steps: How to polish your coastal boat

Polishing a boat, means in general, that you are rejuvenationg the Gelcoat / Topcoat base of your hull. You are sanding a very thin layer of gelcoat and afterwards add a fine (polishing-) film on the sanded and remaing gelcoat. That makes your boat look shiny again and protects it against UV. You also enhance the speed of the boat. Here are some general steps

- Clean the Boat:

- If the boat is dirty or has contaminants on the surface, clean it thoroughly before polishing. Use a boat cleaner, mild soap, and a soft-bristle brush if needed. Rinse with water and allow the boat to dry completely. Read our post about cleaning the hull

- Inspect for Oxidation:

- Check for signs of oxidation or dullness on the boat’s surfaces. If oxidation is left uncorrected, it will accelerate. The rough, deteriorated surface will retain water inside its top layer more than a smooth, hard, shiny, protected surface. If oxidation is present, you may need to use a rubbing compound before polishing. Follow the product instructions for the compound. If you like, buy and use rust converter and apply carefully.

- Apply Rubbing Compound :

- If there is oxidation, apply the rubbing compound according to the product instructions. Use a soft cloth or applicator pad to work the compound into the affected areas. Wipe off excess compound once oxidation is removed. We recommend

- Choose the Right Polish:

- Select a boat polish or wax appropriate for your boat’s material. Different materials may require different products, so refer to the manufacturer’s recommendations. In most cases we apply a combi-product first. A sanding and polishing agent which sands and popolished the surfave. This product simulates a 600-sanding paper where the sanding particles get finer (1000) during application. That means, the polish is a lightly abrasive and has a high content of rich polishing oils that will gorge the pores of a gel-coat finish to maximize color, gloss and shine. After this process we apply a polish.We do not wax our boats.

- Select a boat polish or wax appropriate for your boat’s material. Different materials may require different products, so refer to the manufacturer’s recommendations. In most cases we apply a combi-product first. A sanding and polishing agent which sands and popolished the surfave. This product simulates a 600-sanding paper where the sanding particles get finer (1000) during application. That means, the polish is a lightly abrasive and has a high content of rich polishing oils that will gorge the pores of a gel-coat finish to maximize color, gloss and shine. After this process we apply a polish.We do not wax our boats.

- How to Apply the Polish:

- Apply the polish using an applicator pad or a soft cloth. Work in small sections, applying the polish in a circular or back-and-forth motion. Follow the product instructions regarding application and drying times.

- We recommend to dived the polishing areas. As said: Work section per section. Put the polish on your pad, or on the surface. Both ways work. first make sure you distribute max 4-5 spots in a 1/2 qm area. Not to much. And do not let it dry. Rub it while liqud.

- Be careful: Consider that a gelcoat film has a thickness of 0.4-0.8 mm.

The right Buffer to Buff the Surface:

Once the polish has dried to a haze, use a clean, dry microfiber or cotton cloth to buff the surface. This process removes the dried polish and leaves a smooth, shiny finish. Use a separate cloth for buffing to avoid reapplying polish accidentally. There are different ways to treat the hull and buff the surface.

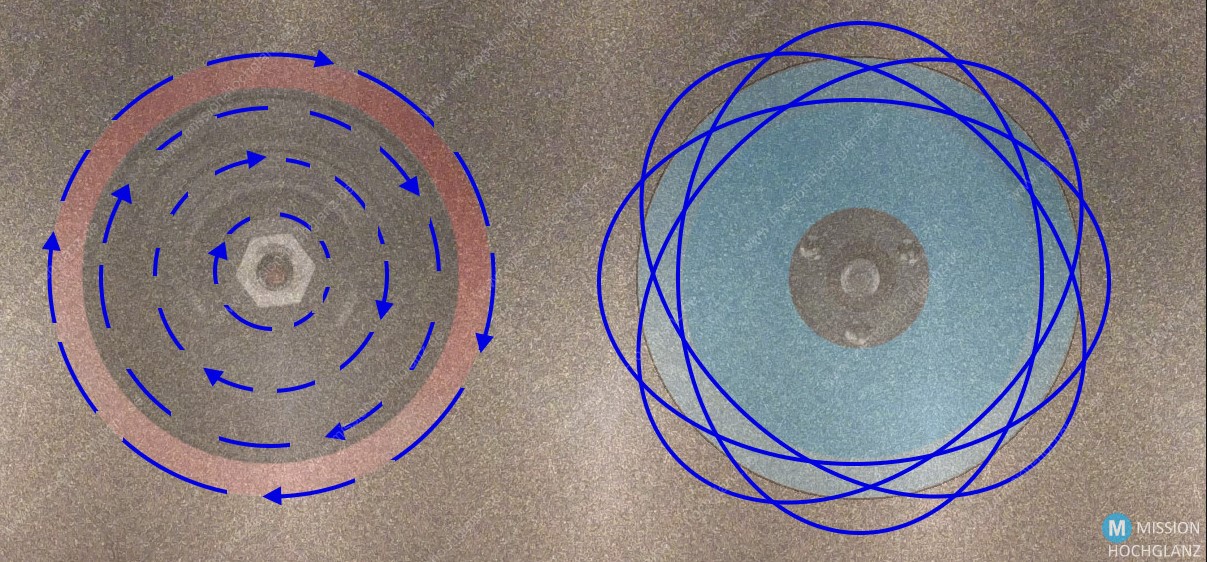

Rotary Buffers

A rotary buffer, also called a rotary polisher with a wool pad is ideal for cutting out gel coat oxidation. Rotary buffers have plenty of power when used with a quality wool pad and a quality marine compound to remove the chalky oxidation and restore a smooth, hard surface. You want to be careful with this machine. Watch out the temperatures on your shell. Move the device regualarily to avoid producing holograms on your hull surface.

Dual Action Orbital Polishers

We mostly use dual action, orbital polishers. They can be used for mild oxidation removal, regular light polishing, and wax application. Also, their polishing pattern reduces the risk of damaging the gelcoat and prevent holograms. These types of tools are the easiest types of tools to learn how to use and make detailing your boat faster and easier than working by hand. Thanks to its forced rotation direct drive orbital action, this type is the choice for boating enthusiasts who want to get the job done fast.

Repeat as Necessary:

Depending on the condition of the boat and the type of polish used, you may need to repeat the process to achieve the desired level of shine and protection.

- Protect Metal Components:

- If your coastal rowing boat has metal components, consider using a metal polish specifically designed for marine use on those areas. Follow the product instructions for application.

- Regular Maintenance:

- Keep to a regular maintenance schedule, depending on factors such as boat usage, environmental conditions, and the specific polish used. Once a year should be sufficient. Remeber the sickness of your gelcoat.

Always follow the product instructions provided by the polish manufacturer, as different products may have specific application and removal procedures. Additionally, be sure to wear protective gloves if required by the product, and work in a shaded area to avoid direct sunlight during the polishing process.

- The end of each coastal season is a good time to thoroughly polish a boat. By removing dirt, salt, sand, oxidation and algae stains and then sealing the boat with a good polish, you’ll ensure that it’s ready to go next year. Plus you will enlarge lifetime and glossiness.

- Get marine polish instead of car polish

- Work section by section. Polishing a boat is a big job.

- Keep a stack of microfiber towels close at hand to buff as you complete each section. It’s even better if you can get someone to help!

- Anytime you’re using a polishing buffer with wool pads and compounds it’s a good idea to wear safety glasses.

- Depending on the size of the boat and the amount of oxidation, you may need several pads to complete the job.

- Keep a bucket of pad cleaning solution close by. When you’re finished using each pad, toss it into the solution to make cleanup easier.

- Most polishing pads can be rinsed or washed with water. Use them 3-4 times.

- Do not polish when temperatures are below 10C degree.

- Do not polish in direkt sunlight. Late afternoons are best for polishing

Gel coat surfaces are not only very hard but they are also very thick (0.4-0.8mm) as compared to automotive clear coats. Polishes made for the marine vessels are more specifically designed for gel-coat finishes. You’ll get better results faster by sticking with products formulated for the marine industry.