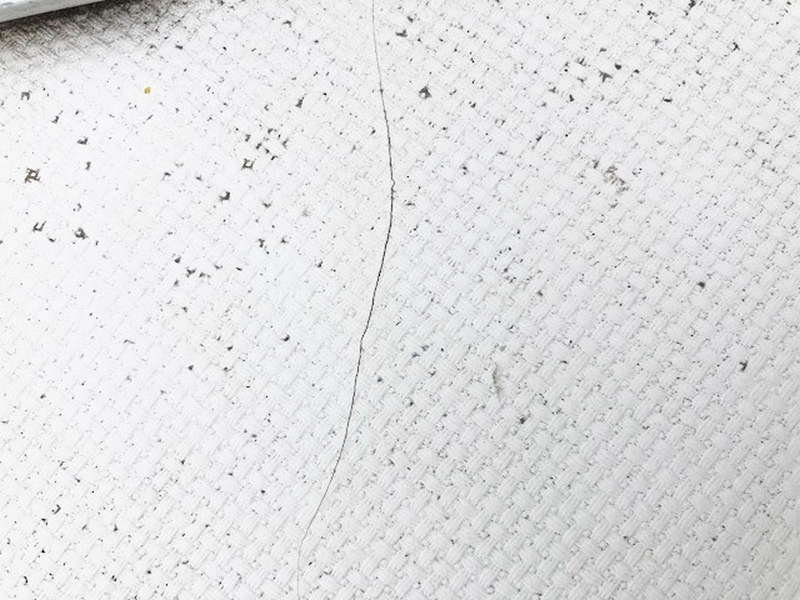

“Help, my Coastal Skiff has cracks on the boat skin.”

Coastal Boats and gelcoat cracks – A problem known to all. A few months ago, we had an interaction with a customer about this that caught our attention. He contacted us because his boat was full of hairline cracks. The gelcoat/topcoat was cracking, even peeling in many places. We looked at the damage and were completely surprised. We had never seen gelcoat damage to this extent. Coastal boats and a chipped gelcoat / topcoat – We really only knew this from very isolated cases. (Read: What is a gelcoat?)

Isolated case or a larger problem?

After some research, we found out: It’s more than just isolated cases. Several other boat owners were surprised to find gelcoat cracks when cleaning their boats. Sometimes even ones that had already flaked off. Furthermore, we have been told about small, fine, almost invisible hairline cracks. How can something like this happen? It isn’t very pleasant, especially when the boat is only a few months old. Whether it’s hairline cracks or spider cracks, it’s not supposed to happen, is it?

Today we want to talk about the causes of this phenomenon. About cracks, the causes of which may already lie in the production process.

Reasons for spider or hairline cracks

We do not know of any supplier that intentionally produces bad boats. All the companies we know work reasonably, with well-trained staff, and are professional. They strive to deliver good quality. Nevertheless, the reality of the boat does not correspond to what is written in the glossy brochure.

Poor production

Most cracks in the gelcoat may have their origin already during the production process of the boat. Hairline cracks occur in places where strong forces must be absorbed. Imagine how your caulking board rails are assembled. A cordless screwdriver is used to screw the rail to the coated laminate. Too much torque and the gelcoat cracks; too little and the rail is too loose. It takes a lot of skill and experience to precisely calculate the pressure of the screwdriver so that no cracks occur. Therefore, hairline cracks often occur when drilling holes for inserts or screws. The pressure “splinters” the brittle gelcoat. Even if they are lightly painted over, they reappear after some time. We have listed the various production defects individually for you here.

Errors in the application of the gelcoat

A poorly mixed or poorly applied gelcoat is another problem. Hairline cracks will also show on the surface if the laminate is too thin. The structure of the boat works a lot when we row through the waves. Our boat is exposed to many different forces, and the hairline cracks often appear in places where strong forces have to be absorbed. If the structure or laminate is too weak, the gelcoat will eventually stop moving under load and crack.

Gelcoat is too thick

This category also includes production defects. Gelcoats are usually applied at a thickness of 1 to 1.5 mm. The thicker the gelcoat, the more brittle it is and the more its elongation at break deviates compared to the laminate. Hairline cracks are inevitable if the laminate is too weak or thin and the gelcoat is too thick. Mixing the gelcoat can also lead to defects. Applying a gelcoat with a catalyst is a chemical process. If the catalyst is not mixed in properly, perhaps even overdosed, it can cause cracking after curing.

Coastal boats and gelcoat cracks – due to an inadequately prepared surface.

If the surface of the laminate is not correctly prepared before the gelcoat is applied, it can lead to a weak bond between the gelcoat and the substrate, resulting in cracks. Imagine production is late and tries to buy time by shortening the sanding process and not cleaning the sanding dust or neglecting the cleaning. The gelcoat will then only hold and adhere for a short time. After some time, usually when the boat is at the customer’s, the gelcoat will chip, crack, or blister.

Nota bene: The gelcoat is generally more brittle and vulnerable than the underlying laminate. The problem worsens over time: on the one hand, the gelcoat hardens and becomes increasingly brittle, and on the other hand, the laminate can soften and bend even more over the years due to frequent alternating loads.

Excessive loads and shocks during assembly, transport, or loading.

During transportation, all boats are subjected to a great deal of stress. Whether on a trailer, in a container, or on the roof of a car. That already starts with the internal transport. Generally speaking, improper transportation can cause excessive stress on the laminate, which can cause cracks in the gelcoat. This stress can occur especially in boat laminates with many fiberglass layers, as the layers can separate from each other, and the gelcoat can crack due to the increased stress. In addition, improper handling during shipping, such as dropping or bumping the boats, can cause the gelcoat to crack due to the impact.

What should I do?

Look at the shape and location of the cracks. These can be in different places: support planks, seat rails, hatches, and safety nets for bottle holders, locate the crack, and determine if any parts like bolts or nuts are lost or loose. You don’t have to go to the shop for hairline cracks; I would still take a photo and show it to an expert, like your boat dealer. He will give his expert comment.

Once you have the comment, you can consider whether talking to the boat manufacturer makes sense. If it is manufacturer damage, almost all boat manufacturers are on your side and will take the necessary action. We know of only one case where the boat owner was unsatisfied with the manufacturer’s proposal.