Are you a coastal rower? Have you ever heard of osmosis? Osmosis on your Coastal Boat – Is this really a thing you should be afraid of? For those who sail or own a boat, this phenomenon is well known. But is osmosis on coastal boats an issue for rowers?

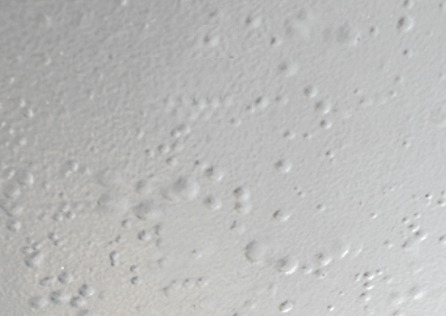

Osmosis means the one-sided diffusion of a substance (usually water) through a semipermeable membrane (the boat skin). The water of the sea or river penetrates the outer coating of the boat which leads to a chemical reaction and small bubbles form as a result. Every one of us has probably seen something like this before.

Osmosis is a process that takes years. It mostly depends on the number of trips, the water and the sun, but maintenance can also be a factor. Most rowers who use their boats only for long distances or beach sprints and training, probably never have experienced it on their own boats.

Osmosis and Coastal Rowing

Generally, osmosis is a factor that should not be underestimated. Nobody wants the small blisters on their boat. The raw materials and the manufacturing processes are very important. In contrast to yachts and sailing boats, osmosis is rarely observed in the world of rowing. Only damaged coastal boats which are used in the sea for long periods of time might be vulnerable. Nevertheless, you can protect yourself when buying a (used) boat and delay the osmosis. But you don’t really have to be afraid. Especially not with new boots.

In general, boat hulls that are manufactured with vacuum infusion have a higher quality than hand-laminated boats and make osmosis even more unlikely to happen. Epoxy- and vinilester-resins also offer more protection than polyester resins – they are more hydrolysis-resistant.

What happened? Errors and mistakes in building processes and materials

Our boat is basically built like a sandwich – A gelcoat on the outside with glass fiber or core fabric laminated on top. There can be many reasons for osmosis but it mostly happens if certain steps in the construction of the boat are cut short or were done in a sloppy way.

Some chemistry (German): styrene is a reaction product within the damp laminate. If it does not fully react (poor hardening in the boat hull), “damp” residues will remain in the laminate. You can smell it sometimes when you open the airbox. If there are still air pockets in the laminate, the osmotic pressure equalization starts: Then water meets styrene and settles in the air bubbles. As a result, the laminate separates from the resin very slowly.

The most frequent sources of error are the use of low-quality materials or the use of non-professional processing methods during the construction of the hull. Nevertheless, environmental influences during the use of the boat should not be underestimated. Let’s have a look at the most common causes:

- The raw laminate did not soak well: it was not properly rolled and laminated. The glass fibres have not been completely saturated with resin.

- Was a ventilation roller used? If not this tends to lead to small air bubbles in the laminate that have not been vented during processing.

- Dosage of the gelcoat / topcoat: The gelcoat layer is too thin or insufficiently linked (over- or under-dosage of the hardener).

- Low-quality materials: The polyester resins and glass fiber mats of the laminate are qualitatively unsuitable for permanent contact with water.

- Maintenance of the boat: the hull should be properly cleaned, small damages should be repaired and the hull should get time to regenerate, for example by drying it properly during winter storage.

Epoxy rather than polyester resin: Are there material differences?

We know from the construction of yachts but also whirlpools and indoor swimming pools that there can be striking differences in the use of raw materials. Orthophthalic resins (ortho resins) have been proven to be the least suitable resins in several tests. Yachts, that are older than 15 years and where ortho resins have been used, are most likely to have osmosis damage.

We found a slightly different approach to the problem of osmosis on boats on an online marketplace for boats:

“15 years is a really long time for a coastal boat. Osmosis in 2036? Who actually cares?”

But even so, we do think it should matter and generally speaking, epoxy- and vinilester resins with or without colour work best. Polyester resins tend not to. With the right maintenance and care, it won’t happen to your boat, but if it does, you now have an idea why it did.